MICRONIZATION

MICRONIZATION

Micronization – Air Jet mills

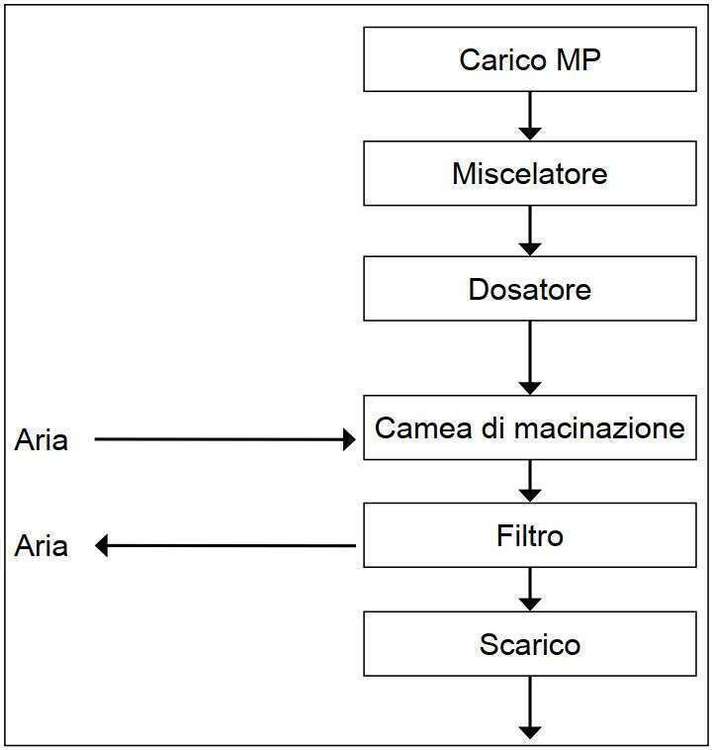

Micronization is a process that allows to reduce the particle size of a product whose granulometry can reach a micron in size as a result of the process.

Micronization makes it possible to reach sizes or particle sizes of the order of microns, unlike a simple grinding for which generally the final order of magnitude we are talking about is around 100 micrometers.

The micronization process is usually carried out by dried compressed air which creates a swirling motion at very high speed inside a micronization chamber that allows the particle size reduction of a product that is channeled inside; the particles, thanks to the collisions between themselves and against the walls of the chamber, become finer as a result of the numerous breakages suffered.

So micronization is a process that does not use mechanical organs in pursuing its purpose, as is in the case of grinding.

The use of compressed air in a jet-mill type system allows you to reach extreme fineness but is not suitable for any type of product. In fact, the collisions that lead to the particle size reduction in the micronization chamber are effective only if the particles enjoy a certain fragility. For example, no effects are obtained by trying to micronize many types of polymers whose particles, pushed by the gaseous fluid, behave like tennis balls, bouncing but not breaking.